sales@clirik.com

sales@clirik.com +86-21-20236178 86-13917147829

+86-21-20236178 86-13917147829

sales@clirik.com

sales@clirik.com +86-21-20236178 86-13917147829

+86-21-20236178 86-13917147829

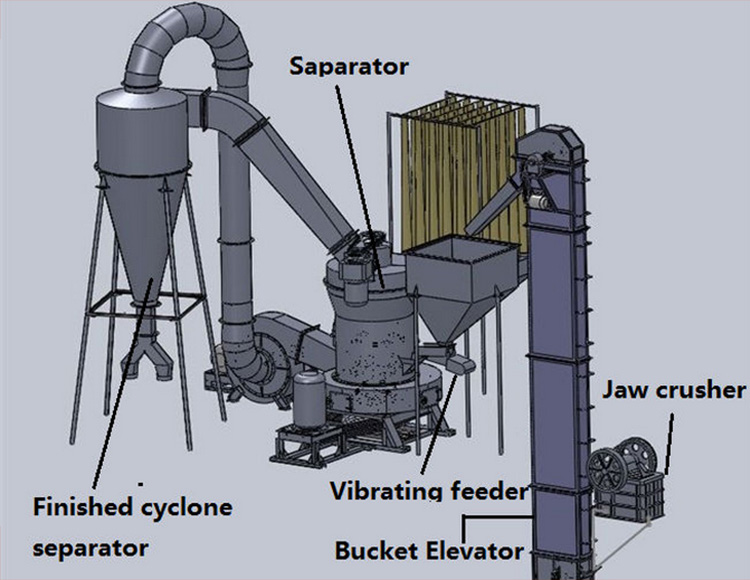

Dolomite Raymond mill is mainly composed of main engine, analysis machine, blower, finished cyclone separator, pipe device, motor and so on. The main engine consists of a frame, a air inlet, a blade, a grinding roller, a grinding ring, a hood and a motor. The auxiliary equipment includes a jaw crusher, a bucket elevator, electromagnetic vibrating feeder and electric control cabinet.

The more fine powder in the material before Raymond grinding, the more influence it will exert on the whole working. Because these fine powder easily adhere to affect the transport. How can we handle this problem? As for the fine powder, they should be screened before the grinding. Before Raymond Mill running, it is necessary to check the closure situation of all repair doors and check whether the gap between the plate of the crusher meets the size of the feed size.

The important parts of Raymond mill in Shanghai Clirik Machinery are made of high quality castings. The sophisticated design ensures the durability of the whole equipment. The harder the material is, the more difficulty the grinding machine will meet.

After starting, it is urgent that add the material immediately-small particles and normal particle size material are supposed to be added at first. Then open the large air volume valve, gradually turn off the small exhaust valve to ensure that the intake port is not outward sprayed on the premise. Users maybe find that the starting mode of the Raymond mill fan is not exactly the same under the condition of different electric capacity. If the capacity of Raymond mill is greater than 30KW, the way of lowering pressure will normally be used. When capacitance is less than 30KW, it can be activated directly.

If you want to know more about our Dolomite Raymond mill or other products, please feel free to contact us. You can chat with us online, leave messages on our website or call us directly.